In construction, procurement is more than a routine task. It drives progress, quality and cost certainty. Delays or poor planning often cause rework, idle resources and higher costs.

Rather than treating procurement as an isolated activity, it is essential to integrate it as part of the broader project delivery system, similar to the design-bid-build approach. This includes clear interaction between the design team, planning function, contracts department, accounts and the tendering process. Each procurement action, especially in contractor-led contracts, whether in public sector procurement or private engagements, must support the project's defined outcomes and not simply follow a standard checklist.

This guide has been prepared to offer a structured and detailed view of the procurement process, specifically for organisations using software such as Xpedeon.

Construction Procurement Defined Within the Project Framework

Procurement in the construction industry refers to the coordinated process of identifying, sourcing, contracting, delivering and closing out materials, equipment, services, or subcontracted works in line with project specifications and delivery milestones. In practice, procurement defines the input readiness of a project and forms one of the key parameters on which progress can either accelerate or stall.

However, describing procurement as a single step or an isolated function misses its operational relevance. The process involves multiple decisions across disciplines and timelines, each carrying its own technical, commercial and contractual implications.

The Functional Scope of Procurement

The procurement process must meet the following primary criteria:

- Technical alignment with approved project specifications.

- Compliance with budget and financial control limits to manage cost effectively.

- Integration with the project construction schedule and look-ahead plans.

- Full traceability of transactions, inspections and approvals.

- Proper vendor engagement, assessment and contractual safeguarding.

If any of these elements are misaligned, the risk of deviation increases either in the form of non-compliant materials, delays in site readiness, unresolved payment disputes, change orders or vendor performance issues.

Typical Workflows in an Enterprise Environment

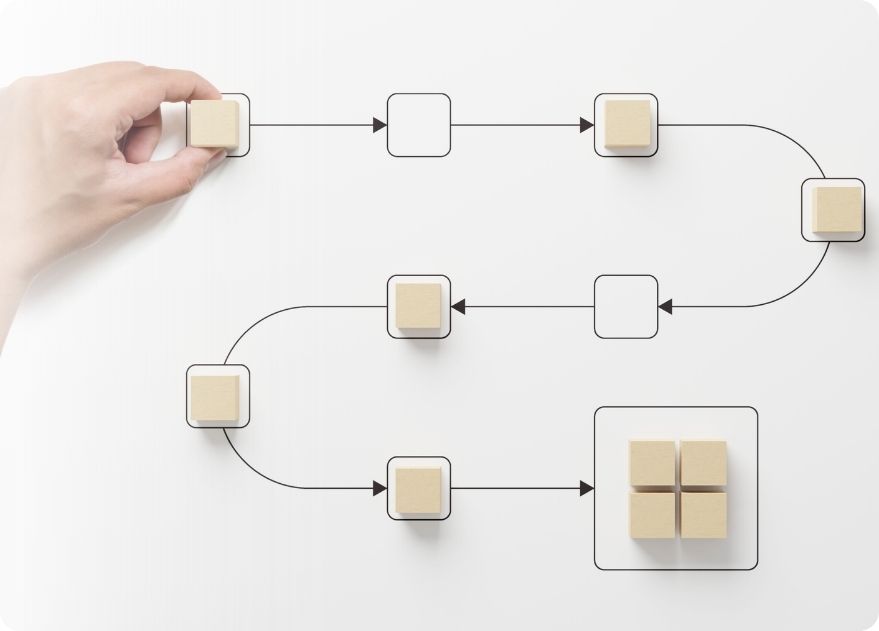

For organisations using a structured project ERP like Xpedeon, procurement is a sequence of defined steps embedded within interdependent modules. Each step, including the preparation and evaluation of tender documents, must be documented, approved and monitored in real time.

A standard procurement workflow includes the following core stages:

- Material Requisition Note (MRN): Initiated by site or engineering based on project requirements.

- Purchase Request (PR): Generated to formally register the need for procurement within the system.

- Request for Quotation (RFQ): Shared with qualified vendors with full technical and commercial requirements.

- Comparative Evaluation: Conducted across suppliers for price, lead time, compliance, low bids and commercial terms.

- Purchase Order (PO): Created and issued, capturing final agreed terms, warranty clauses and delivery schedule.

- Goods Receipt (GRN): Performed after physical delivery, with quality checks and inspection records.

- Invoice Matching and Payment: Managed through accounts, ensuring alignment with the PO and GRN before vendor payment.

Each function is not standalone but part of a continuous flow. The procurement team must therefore coordinate across departments and work within system-defined approval matrices to maintain both traceability and efficiency.

Stage-wise Breakdown of the Construction Procurement Workflow

In an operational project environment, procurement activities, as part of construction management, cannot be reduced to a defined list. Each stage must be tracked, technically verified, commercially validated, and aligned with the construction programme. Below is a structured walkthrough of each procurement phase, detailing responsibilities, control points and what to monitor to ensure procurement remains predictable and fully compliant.

1. Material Requisition Note (MRN)

Objective: To formally raise the need for procurement, based on approved design or construction requirements.

Initiated by: Site engineers, planning engineers, or design coordinators.

Key elements:

- Item description and specification (as per IFC drawings)

- Required quantity and unit of measure

- Delivery location (site, warehouse, subcontractor’s yard)

- Required delivery date based on look-ahead schedules

- Drawing references, if applicable

Xpedeon Notes: MRNs are often raised against work breakdown structure (WBS) codes or cost centres. This links the request directly to budget heads and forecasted quantities, allowing live tracking of material consumption.

2. Purchase Request (PR)

Objective: To escalate the MRN for procurement approval by initiating a commercial request within the system.

Prepared by: Procurement engineer or coordinator.

Reviewed by: Project controls, planning, and quantity surveyor teams.

Control checks:

- Is the specification in line with approved vendor submittals?

- Are sufficient quantities already in stock or pending delivery?

- Does the request fall within the approved budgetary allocation?

Xpedeon Notes: PRs generate procurement commitment logs. These are visible in project dashboards and reviewed during monthly cost control meetings.

3. Request for Quotation (RFQ)

Objective: To invite vendors to submit technical and commercial quotations for the supply or execution of a specific procurement package.

Issued by: Procurement manager or commercial team.

Issued to: Vendors approved through the vendor qualification process.

Inclusions:

- Technical specifications and drawings

- Delivery timelines

- Warranty clauses and terms of compliance

- Commercial terms (INCO terms, payment milestones, penalties)

Xpedeon Notes: The system captures date-stamped RFQ issuance, vendor response logs, and notes from any clarification meetings or revised bids.

4. Technical and commercial evaluation

Objective: To conduct a multi-criteria assessment of received quotations for compliance, competitiveness and alignment with project requirements.

Evaluated by:

Technical review: Engineering/design team

Commercial review: Procurement and contract team

Final recommendation: Consolidated by the commercial lead

Considerations:

- Specification compliance

- Delivery period and logistics feasibility

- Price vs. market benchmarks

- Vendor performance on previous projects

- Contractual flexibility (payment terms, penalties)

Xpedeon Notes: Evaluation matrices are stored as system records. These serve as audit trials and justification for award decisions.

5. Purchase Order (PO) issuance

Objective: To formally award the procurement to the selected vendor, establishing a contractual obligation.

Issued by: Procurement department

Approved by: Project director, finance controller, or as per delegation of authority (DoA)

Contents:

- Itemised BOQ

- Delivery schedule

- Payment terms and conditions

- Inspection protocols and compliance requirements

- Termination and dispute clauses

Xpedeon Notes: PO numbers are generated with system-linked approval flows. Variation tracking and amendment history are maintained under the same PO reference.

6. Goods Receipt Note (GRN)

Objective: To confirm physical delivery, document inspection results and allow inward entry of procured items.

Verified by: Storekeeper or site logistics team

Checked by: Quality engineer or site engineer

Checks include:

- Quantity match with PO

- Compliance with approved sample or submittal

- Visual and functional inspection

- Non-conformance report (NCR), if applicable

Xpedeon Notes: GRNs trigger inventory updates and are essential for releasing the next stage—invoice processing. In cases of rejection, replacement tracking is linked to GRN history.

7. Invoice matching and payment clearance

Objective: To release vendor payment in accordance with contract terms and verified deliveries.

Handled by: Accounts payable team

Inputs required:

- Approved PO

- GRN confirmation

- Delivery note

- Vendor invoice

- Tax and compliance documentation

Xpedeon Notes: Three-way matching (PO, GRN, Invoice) is enforced before payment can proceed. Any mismatch is flagged for clarification, ensuring financial control.

Common Pitfalls in Procurement Execution (and how to avoid them)

Even with the best systems in place, procurement in the construction industry remains vulnerable to several recurring issues. These may seem minor in isolation, but they often escalate into serious delays, cost overruns or even legal exposure. Below is a breakdown of the most common breakdowns in procurement execution, along with grounded, system-aware strategies for addressing them.

1. Late procurement initiation

Typical scenario:

A material request is raised only after site progress is visibly impacted. The procurement cycle, including approvals, vendor coordination and delivery requires more time and can lead to increased cost, resulting in delayed activity or idle manpower.

Underlying cause:

Lack of coordination between site planning, procurement and design functions.

How to avoid:

- Use look-ahead schedules aligned with procurement lead times.

- Xpedeon’s procurement dashboards allow visibility of material demand forecasts. linked to WBS. Ensure these are reviewed weekly in internal meetings.

- Use exception reports to flag high-lead-time items that haven’t yet triggered PRs.

2. Unclear technical specifications in RFQs

Typical scenario:

Vendors submit non-compliant quotations because the RFQ lacked sufficient clarity on material class, standards or finish requirements.

Underlying cause:

RFQ preparation is rushed or copied from previous unrelated packages.

How to avoid:

- Always include approved IFC drawings, specification references and material submittal formats in RFQ packs.

- Conduct a technical briefing with shortlisted vendors before expecting quotes, especially for complex items.

- Store standardised templates in Xpedeon that mandate inclusion of critical technical clauses.

3. Overordering or double ordering

Typical scenario:

Multiple teams (civil, MEP, façade) unknowingly raise PRs for overlapping quantities, leading to unnecessary stock accumulation or financial commitment.

Underlying cause:

Lack of real-time visibility into existing inventory and open POs.

How to avoid:

- Enforce a check against open commitments and GRNs before any new PR is created.

- In Xpedeon, procurement logs by cost code or item can be filtered to detect pending deliveries and prevent duplication.

- Introduce a material reconciliation step at the PR review stage.

4. Delayed approvals due to role ambiguity

Typical scenario:

The PO is stuck in the system for days awaiting approval. No one is sure whether the commercial manager or project director should sign off, especially when it falls in a budget grey area.

Underlying cause:

No clear Delegation of Authority (DoA) defined or implemented in the ERP workflow.

How to avoid:

- Configure the DoA matrix in Xpedeon based on package value, criticality and category (material vs. subcontract).

- Automate escalation if approvals are pending beyond threshold days.

- Maintain a visible audit log so everyone knows where the approval stands.

5. Lack of vendor performance monitoring

Typical scenario:

A vendor repeatedly delivers late or substandard material yet continues to receive orders due to familiarity or absence of documented issues.

Underlying cause:

Vendor evaluations are either not conducted or are poorly documented.

How to avoid:

- After each delivery, ensure that GRN remarks include performance feedback on quality, adherence to delivery schedules and documentation compliance.

- Use vendor scorecards in Xpedeon to track KPIs and flag vendors who fall below performance thresholds.

- Review vendor performance quarterly and update the approved vendor list accordingly.

6. Invoice disputes delaying payment

Typical scenario:

Finance withholds vendor payment because invoice values or tax entries do not match the PO. The vendor is unaware until weeks later, triggering site disruption or escalation.

Underlying cause:

Lack of alignment between procurement, delivery and invoice documentation.

How to avoid:

- Implement a three-way matching system: PO value, GRN quantity and invoice amount must all align before submission to accounts.

- Use Xpedeon to highlight mismatches with colour-coded alerts during invoice entry.

- Train vendors on how to structure invoices to match ERP expectations, including required attachments.

7. Poor change management post PO

Typical scenario:

The scope of supply changes after the PO is issued (e.g., updated spec or drawing revision), but no formal PO amendment is made. At the time of invoicing or final inspection, disputes arise over what was agreed.

Underlying cause:

Verbal approvals or email-based instructions not formalised in the procurement workflow.

How to avoid:

- Any change in scope, quantity, or price must result in a PO variation entry. No exceptions.

- Xpedeon logs all PO amendments with time-stamps and author IDs. Use this feature to ensure version-controlled tracking.

- Conduct internal audits of closed POs to verify that scope changes were properly recorded

Integrating Procurement with Project Strategy

Most guides treat procurement as a functional activity, raise the PR, issue the PO, clear the invoice, much like traditional contracts. But in project environments, especially in design-and-build or fast-track construction, procurement decisions have long-term effects on project margins, timelines, compliance, and risk. Strategic procurement, therefore, demands more than just execution; it requires alignment with the core project drivers and often involves negotiating management contracts to ensure comprehensive oversight and performance.

1. Aligning procurement with the construction programme

Why it matters:

Procurement not synchronised with actual construction phasing results in either stockpiling (raising storage costs) or shortages (causing work stoppages). The aim is to shift from reactive to predictive procurement.

Best practice:

- Integrate look-ahead schedules (2 to 4 weeks) directly with material requirement forecasts in Xpedeon.

- Use project WBS codes to link activities, materials and delivery schedules. This enables smarter triggers for PRs and timely tracking of procurement lags.

- Introduce rolling procurement plans updated monthly based on actual site progress.

2. Involving procurement in design and Value Engineering (VE) decisions

Why it matters:

Many procurement inefficiencies originate during the design stage, specifications that are unavailable locally, or packages that are difficult to source in bulk. Procurement teams are rarely involved in these early conversations, leading to late-stage compromises.

Best practice:

- Make procurement representation mandatory during value engineering workshops.

- Use vendor input to propose material alternates with lower lead times or better warranty terms.

- In Xpedeon, create provisional PRs or “design-stage packages” tagged against unconfirmed scope, these don’t affect budgets but offer early visibility.

3. Managing long lead items (LLIs) separately

Why it matters:

Items such as façade panels, elevators, specialised pumps and imported finishes have procurement cycles that may extend beyond 90–120 days. Treating them as regular PRs leads to tracking failures and disputes.

Best practice:

- Maintain a Long Lead Item Register, directly linked to milestone-based procurement trackers.

- Define vendor kick-off meeting schedules, factory acceptance test (FAT) plans and delivery monitoring tools for each LLI.

- In Xpedeon, these can be configured as individual procurement work packages with dedicated trackers and approval layers.

4. Incorporating contractual risk into procurement decisions

Why it matters:

Not all delays or defects are fully recoverable under contract terms. Poorly written supply agreements often leave contractors exposed to liquidated damages, rework costs, or claims from subcontractors.

Best practice:

- Always involve contract administration or legal teams when drafting POs for critical items.

- Review insurance clauses, delivery responsibilities, penalty enforcements, and dispute resolution terms within the framework agreement.

- Store contract obligations and performance SLAs within the ERP system, ensuring procurement and contract teams are working from the same data.

5. Supplier Relationship Management (SRM) as a strategic lever

Why it matters:

Relying solely on the lowest quote often leads to inconsistency in delivery and quality. Strategic supplier relationships reduce rework, speed up responses and minimise the need for firefighting.

Best practice:

- Identify strategic vendors and categorise them based on value, dependency and repeat engagement.

- Use Xpedeon to maintain a supplier performance index incorporating delivery reliability, NCR count and commercial responsiveness.

- Schedule periodic review meetings and ensure feedback from site, QA/QC and commercial teams is captured systematically.

6. Centralised vs. decentralised procurement – choosing the right model

Why it matters:

Some companies push all procurement decisions to the head office; others allow full site autonomy. Neither model works universally, each has trade-offs in control, speed and cost efficiency.

Best practice:

- For standard items (rebar, MEP consumables, concrete), use centralised bulk procurement.

- For project-specific packages (cladding, fit-out, equipment), empower project-level procurement with necessary approvals.

- Configure workflow permissions and visibility accordingly in Xpedeon. Avoid overriding thresholds manually unless justified and logged.

7. Procurement forecasting and Earned Value Management (EVM)

Why it matters:

Procurement affects both cost and schedule performance indicators. Incomplete visibility here can skew the project's earned value reports and delay recognition of financial deviations.

Best practice:

- Use procurement data to generate committed cost projections in monthly cost reports.

- Link committed, accrued, and actual cost data to EVM metrics for material-intensive activities.

- Forecast potential slippages using exception reports within Xpedeon based on PO ageing and GRN delay analytics.

Digital Procurement from Data Entry to Strategic Control

Digital procurement isn’t just about moving from paper to screen. For construction professionals, it’s about removing ambiguity, increasing accountability, and enabling data-backed decisions across project lifecycles. Yet, most firms stop at basic digitisation, raising POs electronically but miss out on real strategic gains like predictive analytics, cross-project benchmarking, or intelligent alerts.

This section outlines what a fully digital procurement environment actually looks like in the construction industry, with precise steps to move from fragmented processes to integrated intelligence.

1. Eliminate fragmented workflows

Problem:

Design, procurement, commercial, and finance teams often use separate tools, Excel trackers, email chains, disconnected platforms which results in duplicated effort, missed communication, and broken audit trails.

What to do:

- Unify material tracking, procurement, and vendor engagement in a single ERP like Xpedeon.

- Ensure PRs, POs, GRNs, and invoices are not separate entries but part of a continuous, visible transaction flow.

- Enable cross-functional dashboards, such as site engineers should be able to view procurement status just as clearly as procurement managers.

2. Standardise package libraries and templates

Problem:

Procurement packages vary wildly depending on who’s preparing them. This inconsistency causes vendor confusion and increases approval delays.

What to do:

- Build a template library in your ERP for common procurement categories, rebar, blockwork, electrical fixtures, etc.

- Ensure each template includes specification tags, compliance requirements and checklist items.

- Periodically review and refine templates based on vendor RFIs and feedback.

3. Use live procurement dashboards or decision-making

Problem:

Procurement data is often shared in static reports, disconnected from real-time site progress or contract cash flow.

What to do:

- Set up dashboards in Xpedeon that show procurement health by WBS, cost code, or trade package.

- Include flags for delayed PRs, unacknowledged POs and low vendor scoring.

- Make these dashboards available to project directors, not just back-office teams.

4. Integrate vendor portals with compliance management

Problem:

Every time a new vendor is onboarded, paperwork is re-submitted, compliance checks are repeated and delays occur.

What to do:

- Use vendor self-service portals where vendors can update prequalification documents, view PO history and submit invoices.

- Tie compliance (e.g., trade licences, insurances, quality certifications) into vendor activation logic, vendors cannot receive POs unless valid.

- Automate reminders for expiring documents and disable vendors with expired credentials.

5. Link procurement data with project cost control

Problem:

Budgets are approved in the estimation phase, but procurement often ignores budget lines once execution starts, leading to variance and poor accountability.

What to do:

- Map each PR and PO against budgeted line items from the start, not post-factor.

- Lock overspending beyond threshold unless escalated.

- In Xpedeon, configure alerts for budget overshoot, even if delivery has not yet occurred.

6. Automate change order triggers

Problem:

Change in scope or quantity leads to multiple informal instructions and “PO catchups” that later cause disputes or audit flags.

What to do:

- Create rules in your ERP that automatically require a PO amendment or variation for any GRN quantity above the original PO.

- Log every deviation from the baseline procurement scope, including technical approvals or drawings received post-PO.

- Ensure all commercial approvals of changes are logged within the same transaction flow.

7. Move toward predictive procurement analytics

Problem:

Procurement remains reactive responding to site pressure or unexpected shortages rather than pre-empting bottlenecks.

What to do:

- Use historical data to build lead-time averages per item or vendor.

- Trigger early PR reminders based on projected delivery schedules and logistics availability.

- In advanced setups, integrate machine learning tools that flag risk items based on delay history or vendor behaviour trends.

Procurement Defines Predictability

Successful delivery in construction relies less on speed or individual technical expertise and more on how predictably a project unfolds over time. That predictability whether in terms of material readiness, cost management, contractual clarity, or supplier performance rests heavily on how procurement is structured from the very beginning.

Procurement that operates in isolation or depends on disconnected tools, particularly in public sector procurement, tends to introduce uncertainty rather than reduce it. Without direct alignment with project timelines, commercial constraints, and on-site realities, teams are often left making critical decisions with partial information.

Xpedeon addresses this challenge by bringing procurement into the centre of the project ecosystem. Its platform ensures that every procurement action is grounded in real-time data, live schedules, approved budgets, supplier records and contractual obligations, so nothing moves forward in a vacuum.

With this level of integration, procurement becomes a driver of control, not a source of disruption. Teams can plan with confidence, act with precision and maintain clarity across stakeholders and timelines.

For firms committed to delivering on time, within budget and with fewer surprises, the strength lies in placing every order with full context where the programme stands, what the cost exposure is and how ready the site is to receive.

Looking to enable this level of clarity and control across your projects? Book a demo with Xpedeon today.