Key Factors to Pick the Best ERP

Construction firms juggle endless moving parts like projects, budgets, schedules, contracts and crews, often across multiple sites.

Without a unified system, important details fall through the cracks.

Outdated drawings cause rework, misbilled hours go unnoticed and reporting lags days behind.

In fact, a Science Direct study found 45% of construction owners report frequent miscommunication that leads to costly delays or rework.

That's why many contractors turn to a construction ERP (Enterprise Resource Planning) system.

It unifies project management, accounting, procurement, inventory and scheduling under one roof.

In other words, a construction ERP acts as your company's central nervous system, turning siloed field and office data into a single source of truth.

For example, an ERP can log time and materials on-site via mobile apps, automatically update project budgets and generate live dashboards to catch issues early.

Clarify Your Needs and Readiness

Before exploring ERP software, step back, assess and ask these questions:

Why you need an ERP now?

Are you a first-time ERP buyer struggling with manual spreadsheets?

Or

Are you upgrading an old system that no longer handles your volume or complexity?

In either case, start by mapping your current processes.

List out:

- How projects flow from bid to completion, how cost reports are run and where bottlenecks happen.

- Map out key processes that your new ERP should support and note where your existing system falls short.

- For example, you might discover that change orders routinely take weeks to approve or that job costing reports are delayed by data entry.

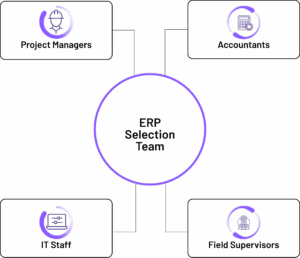

Build Your Team

Next, form a cross-functional team to gather requirements.

Include project managers, accountants, IT staff and field supervisors.

About a quarter of your workforce may become ERP users, so involve those on the ground (foremen logging time, procurement clerks issuing orders) as well as office staff.

This stakeholder analysis ensures the system will meet both field and back-office needs.

Action Steps:

Map processes and pain points: Diagram how projects, budgets and approvals flow today. Identify "hot spots" like frequent cost overruns or missing materials.

Build your team: Include representatives from operations, finance, IT and the field. Define each group's critical needs and workflows.

Set goals and KPIs:

Are you after tighter cost control, fewer delays or better reporting?

Establish metrics now (e.g. reduce change-order approvals from 10 days to 2 days, improve on-time billing) so you can measure the ERP's impact later.

We suggest you consider KPIs like ROI, cost savings and project profitability.

Plan growth:

Forecast how your business will scale in 3–5 years.

If you expect more projects or new business lines, note these future requirements up front (it's easier to build them into the selection than bolt them on later).

Identify Essential Construction ERP Features

Not all ERPs are created equal. Construction ERPs bundle industry-specific capabilities that general-purpose systems lack.

As MDPI academic review notes, construction ERP core modules include budgeting, procurement, progress tracking, site operations and document control.

Think about features that solve your biggest pain points:

Project & Job Management

The ERP should cover the entire project lifecycle. This includes scheduling tasks, allocating crews and equipment, tracking percent complete and updating project timelines.

Seek tools for job costing and billing – for instance, linking work-in-progress updates directly to budgets.

Experts stress

A. Robust Job costing (including labour, equipment and material spend)

B. Project scheduling to manage costs that change daily.

Financial Management

Look for a strong construction accounting system that handles progress billings, change orders, retention, payroll and overhead allocation.

It should produce GAAP financials whilst tying them to specific projects.

For example, if a field engineer logs a cost, it should flow automatically into the project budget and accounting ledger.

CFOs emphasise modules like general ledger, accounts payable/receivable and fixed assets as foundational.

Equipment & Inventory Management

Tracking materials and machinery is crucial. The ERP should manage your inventory (rebar, lumber and supplies) and maintenance of heavy equipment.

In practice, this means bar-code or RFID tagging of stock and vehicles, scheduled maintenance alerts and depreciation tracking.

"Asset and inventory management" is a key feature for construction CFOs.

For example, a bulldozer might be assigned to a project in the ERP; its hours and maintenance costs automatically roll into that job's expenses. This prevents idle equipment and avoids double-booking critical assets.

Procurement & Subcontractor Management

The solution should streamline bidding, purchase orders and subcontractor contracts.

Look for functionality that routes POs for approval, links contracts to budgets and alerts you when subcontractor insurance expires.

Workflow controls (approval chains) prevent unauthorised spending.

The system should also manage vendor catalogues and allow tracking of supplier performance (on-time delivery, quality) to drive accountability.

Document & Change Management

Since drawings and specs constantly evolve, a good ERP includes document control – archiving as-builts, RFIs, permits and safety logs in one place.

Changes (revisions to scope or design) should trigger automated workflows: notify impacted teams, update budgets and record approvals.

In short, the ERP should stop people from working off obsolete blueprints.

Reporting & Analytics

Dashboards are a must.

The ERP should compile real-time data into intuitive reports (profitability by project, cost vs. budget, cash flow forecasts).

Mobile or web dashboards let managers spot cost overruns before they blow up.

CFOs specifically call out reporting & analytics as essential.

For example, a planner on-site might use the ERP's mobile app to see updated material orders, whilst the CFO views a dashboard of all project metrics on a tablet.

Unification and Usability

Unification and usability are just as important as features.

The ERP software should interface with any existing design/CAD tools, payroll systems or CRM you use so that data flows seamlessly (for example, importing a subcontractor list from your HR software).

It should offer a friendly user interface.

Complicated construction work doesn't leave time for a clunky UI.

One guide underscores that user-friendly access (ideally cloud/mobile) and robust security are critical criteria.

Finally, decide early on the deployment model: many firms now prefer cloud (SaaS) ERP to avoid hefty IT overhead.

EY-FICCI surveys show 63% of companies are considering cloud-based systems.

But on-premises can be fine if you need tighter control over data or have limited connectivity.

Match the model to your budget, tech strategy and IT staff capacity.

Feature Checklist: When writing your requirements, highlight must-haves vs nice-to-haves:

- Must-haves: Project job costing, certified payroll, mobile field time entry, budgeting/forecasting, subcontractor/work order tracking, document repository.

- Nice-to-haves: Advanced BI dashboards, drone unification, AI scheduling suggestions or built-in equipment GPS (if they're not critical today, note them but prioritise core needs).

Evaluate and Shortlist Vendors

With clear needs defined, begin researching ERP candidates. Don't rely on vendor brochures alone – seek unbiased info and peer feedback.

Some approaches to follow:

Peer recommendations: Ask your network of contractors or subcontractors what they use. If many similar firms use a particular ERP software, that's a good sign it fits your niche.

Online tools: Industry websites (e.g. Xpedeon) offer filterable comparisons by construction features. There are also tech-prospecting tools that show what software other companies use.

Research case studies: Look for cases (without bias) where ERP software's solved problems like yours. Some vendors publish success stories, but also try finding independent write-ups.

Create Your Shortlist

Once you have a list of 5–10 potentials, narrow it to 2–4 finalists: those that hit 80–90% of your must-haves.

We suggest whittling vendors down by feature fit, industry focus and delivery model.

Ensure shortlisted systems can handle your company size – some ERP software excels at small contractors, others at enterprise scales.

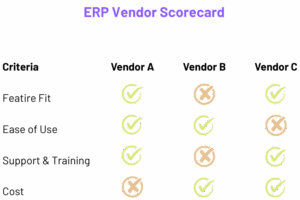

Request for Proposal Process

Next, initiate a Request for Proposal (RFP) or Request for Information (RFI).

Provide your high-level requirements (dozens of bullet points is fine) and ask vendors to detail how they meet each one.

Be sure to clarify any compliance needs (industry regulations, multi-currency, etc.).

When you get responses, create a simple scorecard out of 10: rate each vendor against criteria like feature fit, ease of use, tech stack, support/service level and cost.

This objectivity prevents decisions from boiling down to a single demo impression or salesperson's pitch.

Decision Criteria (Alongside Features):

Vendor experience:

- Has this company focused on construction?

- Years in the industry? Look for solutions built for construction, not just general ERP with add-ons.

- An industry-specialist ERP often means less customisation and a better fit.

Support & Training:

- How will they handle onboarding?

- Do they offer hands-on training, documentation and responsive support?

- Will you get a dedicated consultant?

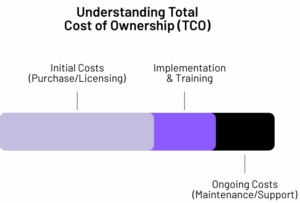

Total Cost of Ownership (TCO):

Beyond purchase/licence fees, consider implementation services, hardware (if on-prem), maintenance and per-user charges.

Make sure to factor in travel costs for training or consultants, as well as internal staff time for rollout.

Curious about how to calculate TCO? Check out the formula:

Evaluation Process

Demos:

Schedule detailed demos with your top vendors. Involve end-users: Have a foreman try the mobile entry whilst a project manager watches.

Ask each vendor to run through your specific scenarios (e.g. enter a change order from the field, generate an AIA invoice, update a schedule). Treat it like a test drive.

References:

Demand references from similar-sized construction companies.

Talk to those customers about their implementation experience, any surprises in cost/time and whether promised benefits were delivered.

Proof of concept (optional):

If feasible, ask for a sandbox or trial period focusing on one project's data.

Seeing your actual data in a candidate ERP software can reveal hidden issues (data formatting, performance, missing features).

Avoid These Common Pitfalls

Keep these reminders in mind as you finalise your choice:

Don't Chase Tech Trends

AI, IoT, etc., are effective but only use them if they serve your needs.

A slightly older but proven system that nails your core processes is better than an untested product that needs constant tweaking.

Beware Over-Customisation

Every customisation can double your costs and make future upgrades painful.

Aim to adapt your processes to the software where reasonable or use configuration settings instead of code changes.

Plan for Change Management

Resistance is inevitable. Keep field crews and office staff involved and informed. Set expectations that the system will change how people work.

Provide thorough training before launch and follow-up support after go-live.

Don't Ignore Data Migration

Cleaning up your existing project, vendor and finance data takes time.

Start data cleanup early (eliminate duplicate records, fix chart-of-accounts inconsistencies) so the ERP is populated correctly from day one.

--> Download our detailed guide on how to avoid common pitfalls in ERP adoption.

Consider Phased Rollout

If you have dozens of branches or complex operations, you might pilot the ERP on a few projects or modules first.

For example, start with project accounting, then add payroll and inventory later. This reduces risk and lets you learn before full deployment.

Next Steps and Checklist

By now you have a high-level decision framework. Here are practical next steps to wrap it up and move forward:

Finalise Vendor Decision

Compare finalists holistically using your scorecard.

Negotiate with your preferred vendor for the best terms (price, implementation timeline, warranty on functionality).

Before signing, ensure the contract spells out support levels and training deliverables.

Prepare for Implementation

Create a detailed project plan.

Assign a project champion who will lead the ERP effort internally.

Clean and transfer data (e.g. chart of accounts, active projects, vendor lists) in the months before launch.

Set up any required hardware or secure cloud access in advance.

Measure Early Wins

Once live, track the KPIs you defined earlier.

Celebrate quick wins (like cutting a reporting cycle from days to minutes) to build momentum.

Use the ERP's reporting tools to monitor ROI: check budget adherence, invoice cycle time, change order frequency or whatever matters to you.

Iterate and Improve

No system is perfect at launch. Collect user feedback, schedule refresher training and adjust processes as needed.

Over time, you can explore adding modules (like CRM or advanced analytics) once the core system is stable.

By following these steps, understanding your unique processes, identifying must-have features, methodically evaluating vendors and planning carefully, you'll select an ERP that not only fits your current projects but also grows with your construction business.

The right ERP can turn fragmented data into insight, prevent costly mistakes and give you a scalable platform for smarter construction management.

Key Takeaway Checklist:

- Map current workflows and pains

- Assemble a cross-functional team (operations, finance, field reps)

- Define goals and KPIs (cost control, on-time delivery, etc.)

- List required modules (project costing, time tracking, procurement, etc.)

- Shortlist ERP candidates (industry-specific, cloud vs on-prem as needed)

- Conduct demos and score (involve end users)

- Check references and review vendor support offerings

- Plan budget & timeline (include implementation costs)

- Prepare data and train staff well before go-live

- Launch and monitor KPIs, adjusting as you go

With this roadmap, you'll be equipped to pick an ERP solution tailored to the construction industry, one that streamlines your workflows, improves visibility and ultimately helps your projects succeed on time and on budget.

You’ve mapped your needs, compared features and learnt the process now it’s time to put that knowledge into action.

Discover how Xpedeon can help you unify workflows and boost profitability. Book Your Demo with Xpedeon today.